Designed advance and state-of-the art technology instrumentation & control for petrochemical, power and oil & gas industries including Supervisory Control and Data Acquisition (SCADA), Distributed Control Systems (DCS) and Process Monitoring Systems.

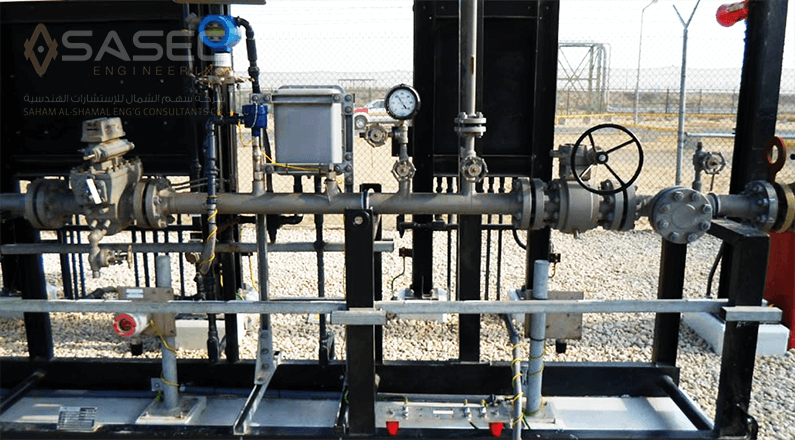

Performed engineering & design of instrument devices for pressure, emperature, flow and level, such as, orifice sizing, actuators, control valves and safety valves sizing, including instrumentation cabling and pressure lead/impulse lines for various type of transmitters.

Undertaken evaluation of new plant Emergency Shutdown System (ESD) and upgrading, using microcomputer-based Programmable Logic Controllers (PLC). Designed installation details of process analyzers, such as Gas Chromatographs,

environmental process monitors, on-line process fluid property analyzers, metering systems for gas & liquid, gas detection and pipeline leak detection systems (LDS).

Designed protective instrument devices for rotating machineries including vibration, temperature, and speed monitoring from field to control room

Our instrumentation engineers have extensive experience in Instrumentation & Control Systems and throughout the Oil and Gas Refineries, Petrochemicals, Power & Process industries. They have skills and experience in the upgrade of existing DCS systems of this type online (hot change-over),SCADA and RMS.

The range of ( I & C ) design activities include, but not limited to:

- Instrument Installation schedules

- Instrumentation database

- P & ID’s

- Points & Lines, Instrument Layout

- Cable & Conduit Schedules

- Vendor data review

- Instrument data hookups

- Loop diagrams

- Flow metering, analyzers, monitoring, field instruments, control panels, chromatography, etc.

- Gas Detection

- Leak Detection System

- Operating & Maintenance Manuals

- Logic Diagrams, Block Diagrams, Cause & Effect

- Detailed Installation Packages

- Functional Specification Documents

- MTO/ BOQ, Materials Requisitions (MR) & Evaluation

- Assistance during Construction & Commissioning