MECHANICAL & PIPING

Our Mechanical & Piping Engineers and Designers are fully experienced in the design of mechanical equipment, tanks, vessels, in-plant piping, cross country pipelines associated with Oil & Gas, Power & Water sectors. SASEC

Conducted design and analysis of various rotary equipment and mechanical systems including, but not limited to, air compressors, pumps, mixers, pressure vessels, tanks, HVAC, water treatment and material handling & conveying. Performed design & evaluation of plant facilities, power plant and pump station. Work included

mechanical building design, fire protection systems (sprinklers, water deluge, foam), drainage, plumbing and related systems.

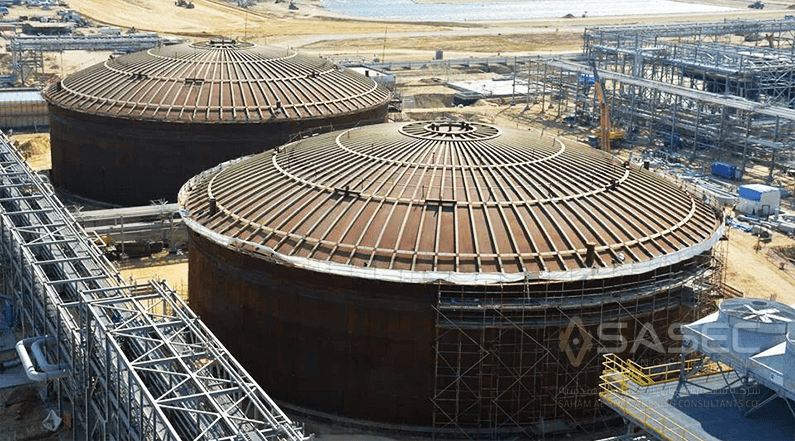

Performed extensive design of storage tanks (vertical upright, horizontal, spheroids) in accordance with API – 650/620, EN, AWWA, NFPA and UL standards from small to large diameters for refineries, tank farm and petrochemical industries using commercial software such as E-Tank and in-house validated calculation

spreadsheets.

PIPING / PIPELINES

Prepared design and construction packages for oil and gas pipelines, including wellhead piping, flowlines, trunk lines and cross-country pipelines in all classifications, underground, surface pipelines on sleepers or on pipe supports and pipe racks for crude

oil, gas, water and chemical liquid conveyance and transportation.

Experience included, but not limited to, in-plant pipe engineering and designs for refinery, gas and oil separation plants (GOSPS), crude stabilizers, utilities and power piping. Conducted flexibility & stress analysis of various piping

systems, steam lines, crude oils, gas lines, NGL, and high-pressure water lines using CAESAR II program, both as standalone project and part of the whole project. Conducted upgrading of oily water and sewer s ystem, design calculations, hot tap packages and reviews of existing piping/pipeline network.

Generated On-stream Inspection (OSI) documentations for piping and equipment in support of plant Corrosion Management Program (CMP).

Conducted hydraulic analysis static, transient & surge for process plant and pipeline network for single &

multiphase mediums, using industry software such as Stoner Pipeline Simulator (SPS) and AFT Fathom, Impulse & Arrows from Applied Flow Technology and ELITE software.

Our design activities include, but not limited to:

- P & ID and Process Flow Diagram (PFD).

- Piping GA, plans, isometrics & pipe support details.

- Specifications & data sheets forequipment.

- Backup Calculations, Studies and Pipe Stress Analysis.

- Fire Fighting & Fire ProtectionSystems.

- Process Piping, Flowlines & Cross-country Pipelines.

- Utilities fuel lines, plumbing, steam piping, compressed air lines, etc.

- Detailed Installation/Fabrication Drawings and Documents.

- MTO/BOQ.

- Technical Bid Evaluation, Vendor Data Review & Purchase Order Recommendation.

- List ItemOperation & Maintenance Manuals.

- Hot tap and Tie-in Packages.

- Assistance During Construction, Pre-commissioning and Commissioning.

- Vessel and Tanks FabricationDrawings.